INNOVATION HUB – RESEARCH AND DEVELOPMENT

Dedicated Research and Development Centre - The Proto Plant develops initial prototypes to validate product and process design feasibility to ensure the product and process meets functional requirements. The Pilot Plant bridges the gap between new product development and full-scale production by enabling process optimization, scalability testing, part handling system automation and quality assurance.

COMMISSIONED INDIAS 1ST 1250T COMPACTION

COMMISSIONED INDIAS 1ST 1250T COMPACTION

HIGH TEMPERATURE SINTERING TECHNOLOGY

Installed a high-temp (1350°C) sintering furnace for stainless steel components with a 100% Hydrogen gas atmosphere.

COMISSIONED 4TH PLANT

A visionary step was taken with the commissioning of our fourth state-of-the-art plant, embodying our commitment to green technology and forward integration.

THE GOVT. OF INDIA AWARDED US WITH EEPC INDIA AWARD

The Government of India acknowledged our excellence with the EEPC India Award, recognizing our significant growth in exports within the Large Enterprise category.

COMISSIONED 3RD PLANT

Responding to market demands, we commissioned our third plant, expanding our scope to cater to the white goods industry.

FASTEST GROWING POWDER METAL COMPANY

Recognized as the fastest-growing powder metal company with an impressive CAGR of 35%, our journey continued upwards.

COMPANY GOES GLOBAL

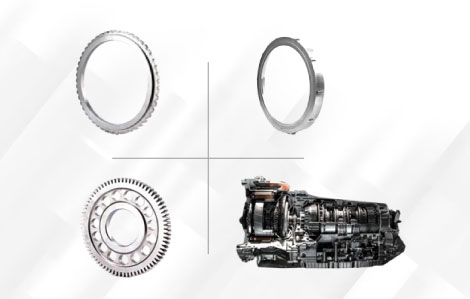

A global chapter began as we proudly became one of the first Indian powder metal companies to gain approval from GM and Ford to supply automatic transmission components for their premium high-selling vehicles in North America.

IN HOUSE TOOL ROOM FACILITY

With the introduction of an in-house tool room, equipped with precision machines and advanced technology, we strengthened our capabilities to meet the dynamic markets critical demands.

COMMISSIONED 2ND PLANT AT SHIRWAL

A significant milestone was achieved when we commissioned our second plant in Shirwal. This plant introduced Indias first 800-ton machine, establishing our commitment to cutting-edge technology.

ENGINE & TRANSMISSION COMPONENT

This year witnessed the expansion of our offerings as we started manufacturing structural engineering and transmission components.

ACHIEVES CORE COMPETENCY IN GEAR DESIGNING & MANUFACTURING

Achieving core competency in gear designing and manufacturing, we became a preferred choice for starter motor gear components across OEMs.

THE COMPANY STARTED MANUFACTURING SHOCK ABSORBER COMPONENTS.

We ventured into manufacturing shock absorber components, rapidly gaining prominence with our homegrown technology and emerging as a market leader for major OEMs.

WE STARTED IN 2001

We Started in 2001 The inception of Speciality Sintered Group marked the beginning of our remarkable journey.