Gear Densification

ROLLING/DENSIFICATION

As we are aware because of inherent porosity of sintered Gears tooth bending strength is less compare to Forging gear which may lead to early fatigue Failure.

Strength and generally mechanical properties of sintered components are directly proportional to the density of the Gear so best way to increase the strength is increase the density in the gear.

To achieve this we have developed a new process called as Gear Densification/Rolling.

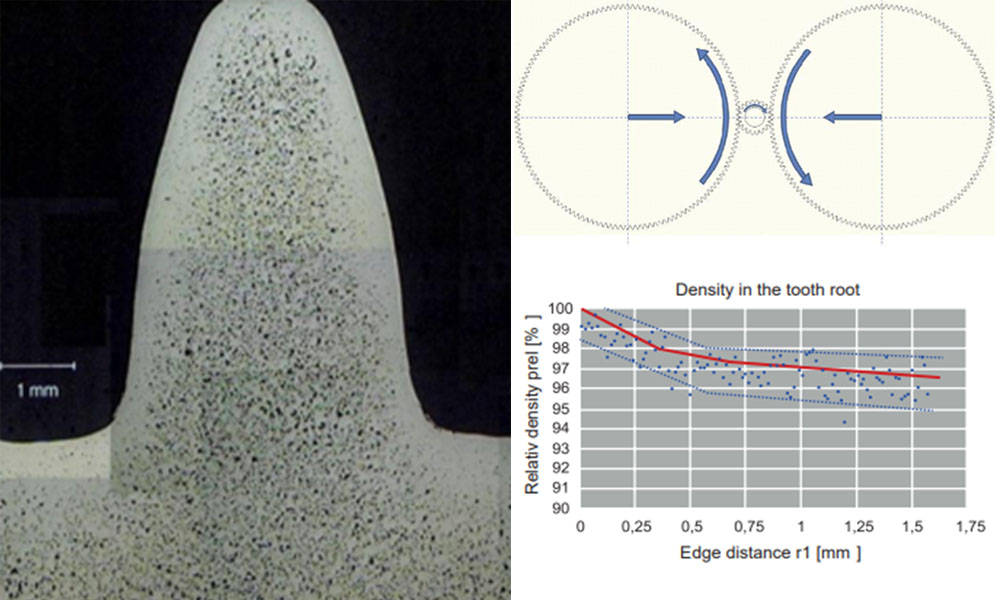

GEAR ROLLING/Densification : The durability and wear resistance of gears of powder metallurgical produced components can be significantly improved by rolling process. While these components usually have a sintered density of approx. 6.9 to 7.4 g/cm³, this density can be increased further in rolled areas to 99.99% of the density of steel, i.e. approx. 7.985 g/cm³ at a depth of up to 0.5 mm from the surface.

Advantages:

- Better wear resistance

- Complex Geometry can be produced

- Improved Surface finish

- Less NVH

- Very Short Cycle time

- Low Cost

- High Fatigue Strength